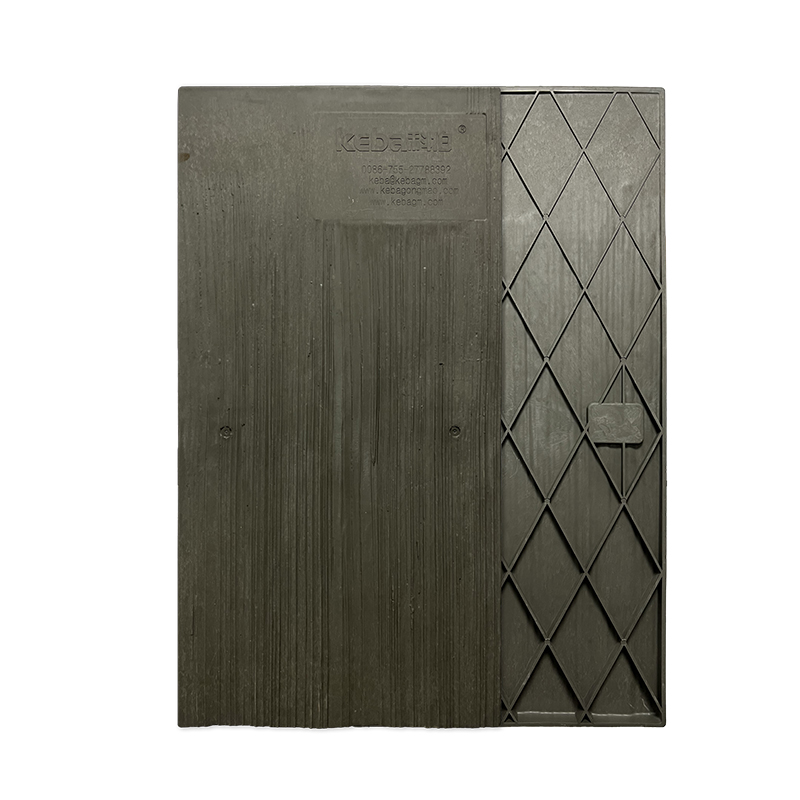

High-Quality Custom Insulation Sheets from Reliable Suppliers & Factories

As a B2B purchaser seeking reliable insulation solutions, high-quality materials are essential. Our Insulation Sheets are designed for exceptional thermal performance, suitable for various applications in construction and manufacturing. Sourced from a top manufacturers in China, these sheets are produced in a cutting-edge facility, ensuring they meet and often exceed industry standards for durability and efficiency. Committed to sustainability, our insulation sheets contribute to energy-saving solutions while minimizing environmental impact. They can be customized in thickness and size, allowing them to meet the specific needs of your projects.Methods To Choose Insulation Sheets Manufacturer Supplier

When selecting an insulation sheets manufacturer supplier, it’s crucial to consider several factors that directly impact the quality and performance of your projects. Since 2006, KEBA has established itself as a global leader in integrated roofing system solutions and high-performance landscape building materials, emphasizing our commitment to innovation and quality. Our extensive experience has enabled us to refine the selection process for insulation sheet suppliers, ensuring that our partners meet the highest industry standards. First, evaluate the manufacturer’s track record and reputation in the industry. Look for suppliers who are recognized for their quality products and services, as this can significantly affect your project's success. At KEBA, we have earned the trust of premier clients by consistently delivering top-tier solutions that enhance both functionality and aesthetics. Additionally, consider the range of insulation materials offered, along with their certifications and compliance with international standards. A reputable manufacturer should provide comprehensive documentation that confirms their products' sustainability and performance metrics. Lastly, assess the supplier's customer service and support capabilities. A reliable insulation sheets supplier should not only deliver products on time but also offer technical assistance and guidance throughout the project lifecycle. At KEBA, we pride ourselves on our collaborative approach, ensuring that our clients receive dedicated support to address any challenges they may face. By carefully selecting a manufacturer who aligns with these criteria, you can ensure that your insulation solutions will deliver the performance and reliability needed for your projects.

Methods To Choose Insulation Sheets Manufacturer Supplier

| Criteria | Description | Importance Level | Evaluation Method |

|---|---|---|---|

| Material Quality | Assess the quality of insulation materials used in the production. | High | Samples testing and certifications verification. |

| Manufacturing Standards | Ensure compliance with industry standards and regulations. | High | Review of certifications and production processes. |

| Production Capacity | Evaluate the supplier's ability to meet your order requirements. | Medium | Site visits and production schedules. |

| Experience and Reputation | Analyze the supplier's experience in the industry and their reputation. | High | Client testimonials and case studies. |

| Cost-Effectiveness | Compare pricing models against the quality of product offered. | Medium | Quotes from multiple suppliers and cost analysis. |

| Customer Service | Determine the level of support and service provided post-purchase. | Medium | Direct communication and feedback from previous clients. |

| Logistics and Delivery | Review the supplier's logistics capabilities and delivery timelines. | Medium | Assessment of delivery terms and past performance records. |

| Sustainability Practices | Ensure the supplier follows environmentally friendly practices. | Low | Verification of sustainability certifications. |

Why Choose Insulation Sheets Supplier Factory

L

Lisa Thompson

I was impressed by both the product quality and the professionalism of the support team. They addressed all my queries swiftly. A fantastic experience!

22 June 2025

M

Michael Johnson

The items I received exceeded my expectations. The after-sales service was outstanding, with knowledgeable staff ready to assist.

19 June 2025

O

Olivia Adams

Every detail of the purchase was attended to. The quality is remarkable and the service is simply professional!

20 June 2025

R

Ryan Carter

These products are just what we needed! Plus, the follow-up service was superb, making the entire transaction smooth.

06 July 2025

D

Daniel Rivera

The quality of the product is excellent. The after-sales support team was very well informed and attentive.

14 May 2025

M

Matthew Morgan

The purchase exceeded my expectations in every way. The team was knowledgeable and quick to respond.

16 June 2025